Ball Valves

Products

Ball Valves

Our ball valves are built at thicknesses never reached before and are made of polypropylene at no load, which offers users higher performance. Quickly opened, just 1/3 switch turn from “open” to “close” position. These valves have the characteristic of a worthless leakage. Due to its total opening passage and plain surface.

General characteristics:

Body and flanges: Polypropylene (see chemical resistance table)

Self-centering ball: Polypropylene or PTFE (Teflon®) with coke

Seats: PTFE (Teflon®) Bolts: Stainless steel Sealing

Ring: EPDM / Viton

O’king Seat: EPDM / Viton

Working Condition: 5kg/cm2 | 1640 F 10kg/cm2 / 680 F

The actued valves pneumatic and electrically regulate the fluid automatically, offering various advantages:

Location remote of the valves to maneuver.

Need to have information about the valve’s position at all time.

Simultaneously functions: Inability to maneuver at the same time if it is not automatic way.

Reliability / repetitive functions: to avoid the possibility of oversights.

Positioning (modulation).

Security: avoid undue maneuvers.

Performing pneumatic and electric.

Cutting valves ON – OFF total step of automatic operation through of actuators pneumatic and electrical being single or double effect.

Available accessories: solenoids valves type Namur, limit cash.

From careér (contact’s switch or inductive) remote location to position.

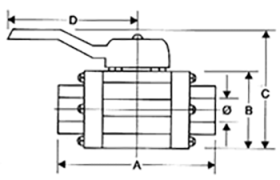

| Dimensions | ||||||

|---|---|---|---|---|---|---|

|

Ø |

1/2″ |

3/4″ |

1″ |

1 1/2″ |

2″ |

3″ |

| A |

89 |

89 |

123 |

146 |

176 |

215 |

| B |

73 |

73 |

100 |

100 |

127 |

172 |

| C |

115 |

115 |

155 |

155 |

185 |

235 |

| D |

135 |

135 |

172 |

172 |

172 |

214 |

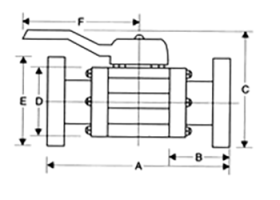

| Dimensions | |||||||

|---|---|---|---|---|---|---|---|

|

Ø |

1/2″ |

3/4″ |

1″ |

1 1/2″ |

2″ |

3″ |

4″ |

| A |

173 |

173 |

205 |

222 |

245 |

294 |

364 |

| B |

69 |

69 |

76 |

82 |

87 |

93 |

132 |

| C |

121 |

126 |

160 |

176 |

190 |

258 |

273 |

| D |

73 |

73 |

100 |

100 |

127 |

173 |

172 |

| E |

95 |

105 |

115 |

150 |

165 |

200 |

223 |

| F |

135 |

135 |

175 |

175 |

175 |

214 |

214 |

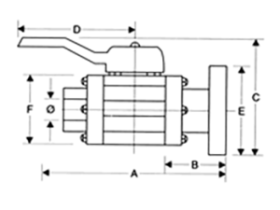

| Dimensions | ||||||

|---|---|---|---|---|---|---|

|

Ø |

1/2″ |

3/4″ |

1″ |

1 1/2″ |

2″ |

3″ |

| A |

132 |

132 |

165 |

186 |

214 |

254 |

| B |

69 |

69 |

75 |

82 |

87 |

93 |

| C |

126 |

126 |

160 |

176 |

190 |

258 |

| D |

135 |

135 |

175 |

175 |

175 |

214 |

| E |

105 |

105 |

115 |

150 |

165 |

200 |

| F |

73 |

73 |

100 |

100 |

127 |

172 |

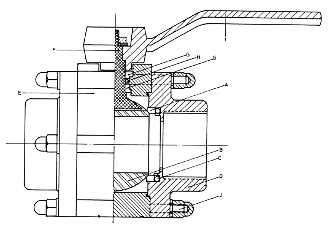

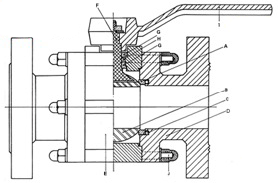

Ball threaded Valves

Cutting plan

A – Ball Seat

B – Ball Polypropylene or Teflon® with coke

C – Ball Seat 0’Ring

D – Cylindrical flange

E – Body

F – Stem

G – Stem Seat

H – Stem O’Ring

I – Handle with antiacid polyamide coating

J- Bolts inox

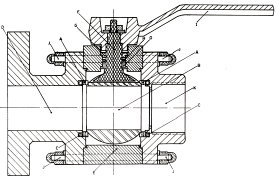

Ball Flanged Valves

Cutting plan

A – Ball Seat

B – Ball Polypropylene or Teflon® with coke

C – Ball Seat 0’Ring

D – Cylindrical flange

E – Body

F – Stem

G – Stem Seat

H – Stem O’Ring

I – Handle with antiacid polyamide coating

J- Bolts inox

Flanged-threaded Valves

Cutting plan

A – Ball Seat

B – Ball Polypropylene or Teflon® with coke

C – Ball Seat 0’Ring

D – Cylindrical flange

E – Body

F – Stem

G – Stem Seat

H – Stem O’Ring

I – Handle with antiacid polyamide coating

J- Bolts inox

K – Flange reel

Contact Bomplast

Address

Fournier 2653/55 (C1437DCK), Autonomous City of Buenos Aires, Argentine Republic

Phone and Fax

(54-11) 4922-8480

(54-11) 4925-5647

info@bomplast.com.ar